Quadcept : Creating Footprints

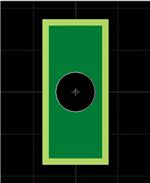

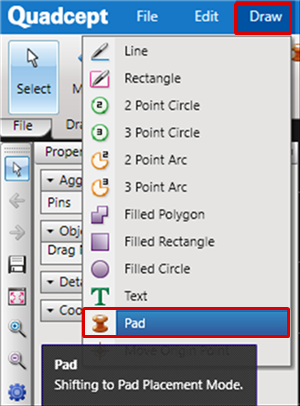

STEP 2: Place Pads

Pads are land shapes for electrically connecting PCB component terminals.

The following will explain how to place pads.

| Placing Pads |

| Place a component pad. |

|

|

|

|

|

|

|

|

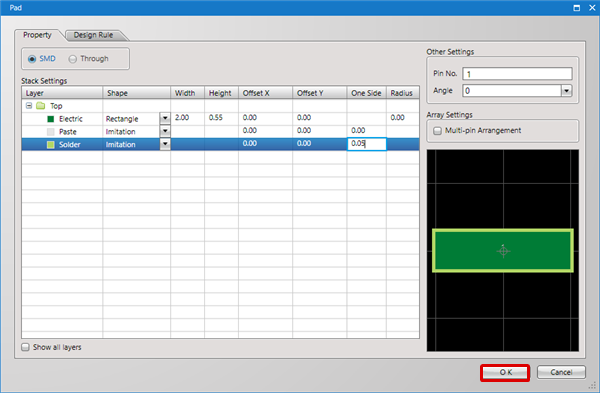

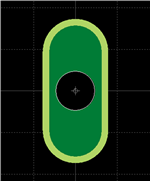

Pad

Pad Type

| Type | Content |

|

SMD |

Pad without a hole. Pad shape for surface mounted components such as Chip components. |

|

Through |

Pad with a hole. Pad shape for through hole mounted components such as Dip components. |

Layer Settings

| Item | Content |

|

Top |

Sets the land size of the Top surface. |

|

Inner |

Sets the land size of the Inner layer. (For the Inner layer, all are the same size.) |

|

Bottom |

Sets the land size of the Bottom surface. |

Layer Type

| Item | Content |

|

Electric |

Sets the copper layer. These are land settings. |

|

Paste |

Sets the area where paste solder is applied. |

|

Solder |

Sets the solder resist area. |

Land Settings

| Item | Setting Contents | Content |

|

None |

None |

|

|

Circle |

Width (Diameter) |

|

|

Square |

Width Radius |

|

|

Oval |

Width Height |

|

|

Rectangle |

Width Height Radius |

|

|

One Side (One Side over size) |

Settings can be configured based on the size of the land (Electric layer). |

When a Radius is input for a Square or Rectangle, you can specify the roundness of a square pad.

Drill Settings

* This can only be set when "Through" is selected as the pad type.

| Item | Content | ||||||||

|

Shape |

Sets the drill shape and size.

W: Width |

||||||||

|

Tolerance |

Sets the tolerance for the drill diameter. This is shown for NC Drill Files and Print NC Drill Lists. |

||||||||

|

Plating |

Possible to set whether to plate a hole. Normally, "Plating" should be checked for component pads. |

Other Settings

| Item | Content |

| Pin No. |

Specifies the Pin No. |

|

Angle |

Specifies the Angle. |

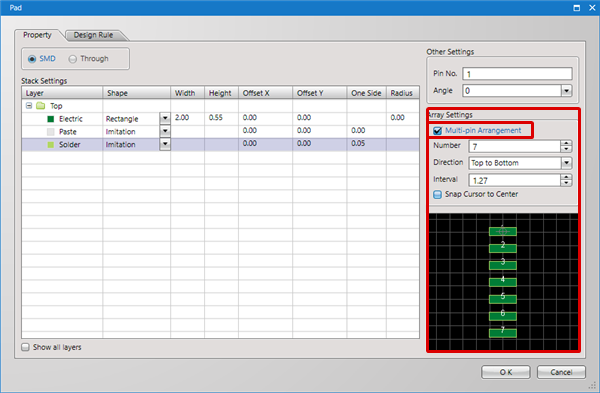

Multi-pin Arrangement

When Multi-pin Arrangement is enabled, multiple pads can be placed together by specifying the Number, Direction, and Interval for pad placement.

| Item | Content |

|

Number |

Specifies the number of arranged pads. |

|

Direction |

Select either "Top to Bottom", "Bottom to Top", "Left to Right", or "Right to Left". |

|

Interval |

Sets the pad-to-pad interval. |

|

Snap Cursor to Center |

Check for whether to place by snapping the cursor to the center of multiple pads. |

For more details about the pad sizes that our company uses, refer to "Reference: Pad Dimensions".